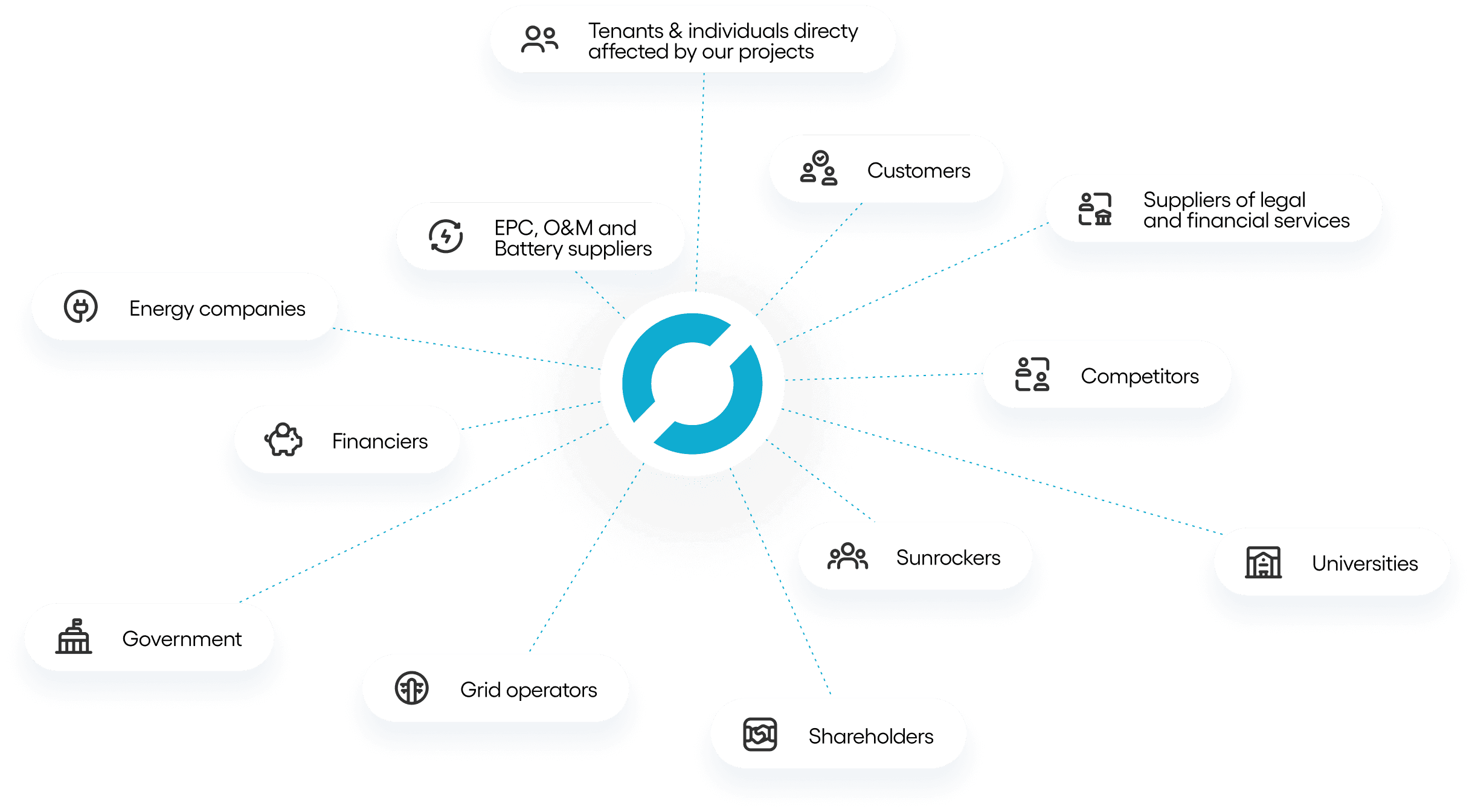

Stakeholders and supply chains

In 2022, we prioritized our internal competence to understand and address the material impact of our operations on people and the planet. It required a thorough understanding of the stakeholders affected by the company's activities.

To identify these stakeholders, Sunrock engaged employees from different departments and disciplines, as well as the company's leadership. The process also involved reports from government institutions, civil society organizations, and stakeholder input. Sunrock employees and the workers linked to our supply chain are our most material stakeholders in terms of actual and potential ESG impact. Many workers in the Sunrock supply chains are often located in countries where fundamental labor rights are not adequately protected.

Sunrock works on identifying the actual impact on people and communities in its supply chains through, among other things, conversations with producers of components and on-site audits. Our initial focus is on the impact of the construction of our parks and manufacturing of main components.

For Sunrock, the material stakeholders in its supply chains also include communities affected by mining operations for minerals used in the components we source. The actual and potential environmental impacts of our supply chains are also in scope, for which we need the cooperation of our EPC as well as Operations and Maintenance partners .

Supply chain ESG challenges

In 2022, Sunrock constructed approximately 200 MWp of PV plants. Challenges in building solar projects include the rising costs, availability of materials and labor shortage. Moreover, visibility into and access to credible data about the social and environmental impacts at different nodes of the supply chains remains an issue of major concern. The critical goods needed in our solar parks often come from countries where raw materials are extracted, metals are produced or (semi-) products are manufactured, with poor track-record of complying with international social and environmental standards. International norms that protect worker and community rights, as well as the natural environment are not always respected in such countries.

Strengthening our upstream ESG approach is critical in our efforts to address actual and potential negative impacts we may come across in our supply chains. One of the first steps we have taken is to structurally add ESG as a topic in our regular meetings with (PV module) suppliers. In the mid-long run a local (European) supply chain with better transparency on labor and materials sourcing is required. We need the upcoming years to prepare for that transition.

Feasibility

study

Commercial close

(lease signed)

Technical close

(“TC”)

Financial close

(“FC”)

‘Project close’

Construction

start

COD

PAC

1

2

3

4

5

6

7

Design engineering

EPC DC proposal

EPC AC proposal

Yield /PR

Grid connection method

Design allignment with insurance company Client/tenant

Design verified

Stability

Roofer confirmation

Grid confirmation from DNO

EPC agreements signed

Bankable TDD reports

Bankable TDD agreement

Engineering

Feasibility

TDD

Achieve operational excellence and hassle-free process for clients, ensure safety and project quality

Solar project development process

EPC

Technical close

Roof warranty

Grid capacity

Structural and stability study

Freek van Gijn

Supply Chains Manager and chairperson ESG working group on Supply Chain Transparency and Accountability

Engaging with suppliers to improve ESG performance

The success of our projects depends on the quality of our partnerships. We work together closely to ensure we deliver high-quality, smart solar energy solutions that meet the needs of our customers while minimizing our social and environmental impact.

EPC and O&M partners

Sunrock collaborates with a diverse range of partners across our processes. Our most significant suppliers in terms of ESG impact are Engineering, Procurement and Construction (EPC) partners, as well as Operations and Maintenance (O&M) partners. Sunrock has long-term, transparent relationships with EPC partners. The collaboration is based on turnkey project agreements, and the EPC partners are fully responsible for the entire installation of the PV project, including the procurement of all goods needed to realize the project. Sunrock's Operations and Maintenance (O&M) partners ensure the smooth operation of installed solar panels. These partners are responsible for the ongoing maintenance, repair, and replacement of the PV-components when needed.

The process

After reaching agreement with owners and/or tenants of real estate to install PV modules on their roofs, we initiate a process for financing and realizing the project. We take care of the necessary permits, insurance, and other administrative requirements. Sunrock keeps the building's users aligned and incorporate their input. During construction, Sunrock remains fully involved regarding quality, health & safety, and supply chains responsibility. Together with our EPC partners we improve the performance of the project in these fields.

Health, Safety &

Environment

We expect our partners to abide by our supplier code of conduct and health, safety and environment (HSE) guidelines. EPC partners draft an HSE plan prior to a project, checked by independent HSE assessors. HSE audits are conducted at the start of each project as well as at the completion. The independent auditors report directly to Sunrock. To make the necessary improvements, we work together with the partner. HSE issues identified on sites are registered in a system and warranted projects may be stopped immediately. We live by a strict record keeping policy concerning HSE. Incidents and any actions taken are discussed in management reviews.

Engagement

Sunrock conducts operational calls every week with main suppliers. Once a month, we meet with the management of our EPC partners to discuss planning, progress and HSE topics. Sunrock engages at least once a year with the management of EPC partners on broader ESG matters. Intermittent meetings are scheduled to discuss specific issues. Additionally, we regularly speak with manufacturers of the main components of PV-systems about ESG in their operations and supply chains.

Outlook 2023

Sunrock will intensify ESG conversations with our tier 2 suppliers in 2023, to gain more insights on the production conditions of our capital goods.

Engaging with suppliers to improve ESG performance

Sourcing responsibly

for positive impact

In 2021 and 2022, Sunrock began a journey to truly comprehend the impact through its supply chains. We reviewed reports from the United Nations, universities, and different media outlets on the matter. Moreover, we assessed our own impact on people, communities, biodiversity, and climate change.

The assessment contained:

holistic mapping of the products and services essential to Sunrock.

life cycle assessment, to determine greenhouse gas emissions in the value chain.

high-level human rights and environmental supply chain mapping, to identify primary issues potentially linked to the value chain.

desk-mapping of ESG maturity of direct suppliers (1st tier), to gather insights for supply chain due diligence actions.

Supplier Code of Conduct

In 2022, Sunrock took major strides towards enhancing our commitment to sustainable practices by launching a Supplier Code of Conduct. The development of this code was informed by conversations with various stakeholders and insights gained from assessments. The code outlines the expectations we have for our most relevant suppliers and requires them to undertake human rights due diligence in their operations and supply chains.

Participation

Since its launch, 80% of our suppliers (in terms of our investments) have signed the Supplier Code of Conduct, demonstrating their dedication to sustainability. To ensure compliance with the expectations formulated in the code of conduct, we conduct annual comprehensive assessments and engage with our suppliers to adopt actions for progressive ESG improvement. By taking a collaborative approach, we help our suppliers achieve positive and sustainable results.

This simplified overview of the PV system’s supply chain shows the major producing countries of the raw materials linked to a PV-components or semi-products. It is a summary of the holistic ESG supply chain mapping conducted by Sunrock in 2022, using information from the United Nations, reports from the International Energy Agency and other publicly available sources . The overview displays examples of human rights and environmental risks, linked to the solar supply chain. They do not necessarily reflect the exact countries and specific risks linked to our supply chain. Neither does the list denote the severity of the risks in these countries. We are in the process of researching the specific impacts of our supply chain. Ultimately, this knowledge will define the actions necessary for improving supply chain conditions.

Material circularity and responsible sourcing are key considerations in the procurement of office supplies and other necessities.

Many of our supplies come from local companies committed to social and environmental sustainability.

All of our pens and books are made from recycled materials.

We are increasing the lifespan of office chairs, including repairing and upholstering 16 chairs in 2022.

Newly purchased chairs are made from PET-bottles.

We repair (instead of replace) computers and telephones, whenever possible.

We purchase responsibly produced food, offering a diverse daily range of options. In 2022, Sunrock kicked off offering vegetarian only lunches for a week per month.

We donated food supplies to charities in the Fall of 2022, in collaboration with our employees.

To reduce plastic waste, we provide our team with Dopper bottles at events.

We visit external locations for company events by bus or public transport as much as possible.

All this is part of our effort to reduce the climate footprint of our offices and events.